Traditional Methods Brought Up-To-Date.

(View French version) The techniques involved in some jewellery making processes have almost disappeared, nevertheless they can have advantages that should not be forgotten.

Until the '70s, artisan jewellers learned to make casts with cuttlebone to create of purely solid pieces. The know-how involved in this process has been preserved by José ACTIS, a craftsman in Saint-Jean-Cap-Ferrat, France. José warmly welcomed us into his workshop this month, so now we will share this technique, fortunately not lost forever.

The Cuttlefish Bone and its Advantages

Cuttlefish is a mollusc that has an internal buoyancy system commonly called ‘bone’. This highly porous and air-rich material is composed of aragonite ( calcium carbonate ) and trace elements used , among other things, for feeding birds. The cuttlebone, white and oblong, is actually an internal shell which allows the decapod ( 10 armed mollusc) to conserve its energy naturally when travelling in the seabed.

It is Nature's gift to the jeweller who can use it as a mould after having made an imprint, in order to cast alloyed gold or silver. It is an ancient technique which remains very manageable for those who want to devote some time to it.

The cuttlebone is lightweight, easy to work with and does not present any toxicity or pollution. In addition, during the casting of the metal, it gives off barely any smoke and with the basic tools of an artisan jeweller, it is possible to create a solid seamless piece such as a signet ring or any small shape required.

Lastly, its low cost and good availability throughout the year make it a tool of first choice for designs intended for customers who want quick delivery and particularly appreciate fine craftsmanship. In addition, it makes it possible to avoid the delays in delivery inherent in industrial techniques (today, the basic form is simply delivered to the creator).

Drawbacks

José underlines that care must be taken in the choice of sizes and thickness of cuttlebone before execution. He reminds us that certain matrices may particularly have many structural internal striations to be taken into account ahead of his work. This photo (photo 2) presents the details of these streaks in a gold piece that has been cast, these will need to be eliminated with a file.

Preparation

After choosing a cuttlebone of the right size for the shape moulding (photo 1), the jeweller's saw is used to divide it into two and eliminate the brittle ends (photo 3).

The two parts are fitted to each other with the file and the jeweller's saw and ( photo 4 ) then polished against the other tender side to obtain a perfectly smooth contact surface and homogeneous grains. The sealing of the mould is improved.

The basic pattern previously made of wood , wax or lead is then used to take an impression of the model in half its thickness in one of the two halves of the mould ( photo 5) . The second half is now carefully pressed against the first on its other half thickness (photo 6).

Benchmarks, previously drawn with the file and the jeweller's saw, ensure a good match between the two negatives.

The shape casting is now stamped in the mould. José separates the two parts to extract the model from which the imprint must be perfect. A moulding aperture through which the precious liquid metal will run before filling the available mould space available is delicately crafted in each part of the mould (photo 7) before they are firmly linked the to each other using a iron wire (photo 8).

Finding Air Bubbles

José explains that the ancient craftsman were in the habit of directing a thin strip of zinc in the moulding hole to avoid the random and catastrophic formation of air bubbles during the casting of the metal. Additionally , the creation of a very fine air outlet (the size of millimetre using jeweller's saw) extending upwardly from the negative mould to the entrance of the cast offers an air exit. Indeed, the porous nature of the bone has the advantage of not having truly need of it.

Care in Use

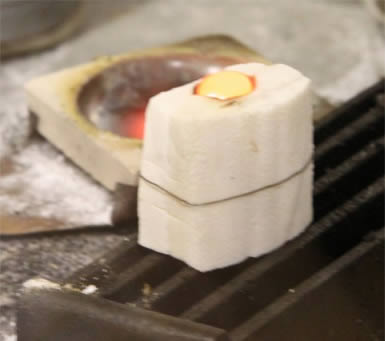

Now, the mould is finished and ready to be used (photo 9). José has chosen the precious metal with from which he will create his signet ring. Three points are worth noting:

- Metal weight is multiplied by 2 for a silver signet and 2.5 by weight for the gold signet.

- The size of the finished signet will be about 1/10th lower than the basic model, the cast metal shrinks during solidification.

- The palladium gold that today replaces nickel does not give as good a result with this technique compared to the older nickel alloy.

Metal casting (photo 10)

It is now time for the delicate freehand operation of casting the gold into the mould. The metal is melted in a refractory crucible with the welding torch. It is the most beautiful and powerful moment of the work. The cuttlebone suddenly seems extremely fragile faced with the driving force delivered by gold brought to a melting temperature of more than 1000oC. José remains focused. With an unerring hand, he quickly pours the gold in the mould. The operation is a success and José will give us a second version, this time with silver alloy.

Following once again the series of steps described above. Photos 12 & 13 illustrate the appearance of the second mould at his opening, once the titrated silver has been poured and cooled... allowing us the opportunity to relive those moments of magic that only the skill and knowledge of the true craftsman can provide.

Conclusion

Metal casting in the mould is the most delicate operation and should proceed rapidly. Each trapped air bubble in the mould generates a lack of matter in the shape of the trapped of the air pocket and results in holes, so the casting must to be done again.

When the operation is successful, the extracted object requires a perfect finish. The shape of casting hole is separated from the body, the signet worked from the inside of the ring body to the outside with the file and then the emery stick before being gently polished. The cuttlebone will be unusable for any further operation. ‘One cuttlebone, one cast!’ says José.

Author

- Caroline Mergalet FGA

- Independent Jewellery Valuer

- Villefranche Sur Mer, France

- Gem' Expertise

Topics

- Manufacture (primary)

- Jewellery

Intended Audience

- Consumers (primary)

- Students

- Appraisers / Valuers

- Academics

Content

- June 2020

- 5 mins reading time

- Dale-Chall readability level:

Easily understood by an average College Student - 7 mins speaking time

- 0 Comments

About the Author

Share

Share this page on your favourite networks

Comments

To avoid spammers, your comment or question will published after it has been checked.

Consumer advice can be found in the Consumer Resources section, this contains information to assist the jewellery-buying public, for example: Types of Jewelry Appraisals and Jewelry Trade Asociations etc.